Stop Guessing, Start Saving: Slashing Boiler Downtime and Operational Costs with IoT Remote Diagnostics.

The recent boiler explosion in Selangor is a stark reminder of the inherent risks and immense responsibilities that come with operating industrial boilers. On 03 May, a devastating boiler explosion at a palm oil factory in Bestari Jaya, Selangor, resulted in four workers suffering serious burn injuries, with one critically affected. Such incidents are not just statistics; they represent profound human tragedies and catastrophic operational failures that send shockwaves through the affected businesses and the wider Malaysian industrial community.

Beyond the immeasurable human cost, events like these underscore the severe financial and reputational damage that can occur when boiler systems fail. For many Malaysian businesses reliant on steam, the traditional approach to boiler maintenance often involves a degree of “guesswork.” This can lead to servicing equipment too early, wasting resources, or far more dangerously, too late – paving the way for critical failures, costly emergency repairs, devastating production losses, and in the worst cases, tragedies like the one in Bestari Jaya.

The rising costs of energy, skilled labor, and the intense competitive pressures faced by Malaysian industries demand a smarter, safer, and more precise approach. It’s time to move beyond outdated practices. At SteamBytes, we’re helping Malaysian businesses transition from this uncertainty to a future of precision boiler management, powered by cutting-edge Internet of Things (IoT) remote diagnostics. It’s time to stop guessing and start saving.

Understanding the Power of Connection: What is IoT?

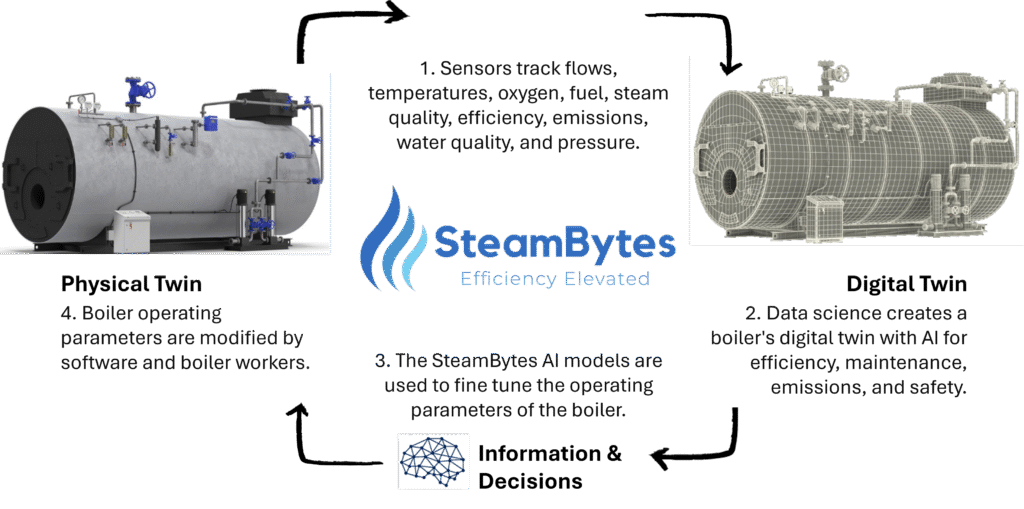

Imagine everyday objects – your factory machinery, your delivery vehicles, even appliances in your home – being able to “talk” to each other and to you over the internet. That’s the core idea behind IoT. It involves embedding physical objects with sensors, software, and connectivity. These connected “things” can collect and exchange data, allowing for smarter decisions, automation, and unprecedented levels of insight and control.

Think about smart home devices that let you control your lights or air conditioning from your phone – that’s a simple example of IoT. In an industrial setting, IoT takes on a much more powerful role, connecting vital machinery like your boilers to intelligent systems that can monitor, analyze, and help you manage them more effectively than ever before.

IoT for Industrial Boilers: More than just Basic Alarms

When we talk about IoT for boilers, we’re going far beyond simple alarms for high temperature or low pressure. We’re talking about a comprehensive system that provides a deep, real-time understanding of your boiler’s health and performance:

Smart Sensors, Constant Vigilance: A network of sophisticated sensors is strategically placed on your boiler’s critical components. These sensors continuously monitor a wide array of parameters – temperature, pressure, vibration, flue gas composition, water quality, steam flow rates, and more. They are the eyes and ears on your equipment, 24/7.

Secure Data, Seamless Transmission: This vital data is encrypted and securely transmitted in real-time to a robust cloud platform. Our systems employ industry-best practices to ensure your operational data remains confidential and protected.

The Power of Advanced Analytics & AI: This is where the real intelligence lies. Sophisticated algorithms and Artificial Intelligence (AI) analyze the incoming data streams, identifying subtle patterns, anomalies, and deviations from optimal performance that would be invisible to the human eye. This isn’t just about flagging a problem as it happens; it’s about predicting potential failures before they occur.

Actionable Insights, Not Just Raw Numbers: The system doesn’t just overwhelm you with data. It translates complex information into clear, understandable insights and prioritized alerts. Your maintenance team receives specific notifications about what needs attention, why, and the urgency, allowing for targeted action.

Access Anywhere, Anytime: Whether you’re at your facility in Johor Bahru, in a meeting in Kuala Lumpur, or even overseas, you or designated SteamBytes experts can securely access this diagnostic information and performance dashboards via a computer or mobile device. This remote capability is crucial for timely decision-making.

The “Precision” Advantage: How Remote Diagnostics Saves Your Business Money

The Power of AI & Remote Monitoring: Artificial Intelligence algorithms continuously analyze sensor data, detecting subtle anomalies that predict potential failures weeks or even months in advance. When a potential issue is flagged, Remote Monitoring ensures you receive instant alerts on your phone or computer, no matter where you are in the world. This allows you to proactively schedule maintenance during planned shutdowns, avoiding those catastrophic failures that halt operations unexpectedly.

Improve Fuel Efficiency & Reduce Soaring Energy Bills: Energy costs are a major concern for Malaysian industries. SteamBytes can be a powerful ally in your fight against energy waste. The system can provide:

- Inefficiencies in combustion processes.

- Subtle heat transfer losses.

- Real-time data, You can fine-tune your boiler operations for optimal fuel consumption, directly impacting your operational expenditure (OPEX). Every percentage point in improved fuel efficiency translates into significant savings.

Extend Boiler Lifespan & Protect Your Investment: Boilers represent a significant capital investment for any Malaysian business. Remote diagnostics help protect that investment. By detecting and addressing minor issues like early-stage scaling, subtle corrosion, or component wear before they escalate, you prevent major damage that could drastically shorten your boiler’s operational lifespan and lead to premature replacement costs.

The era of reactive, guesswork-based boiler management is over. For Malaysian industries to thrive in an increasingly competitive global market, embracing smart, data-driven solutions is no longer a luxury but a necessity. IoT remote diagnostics offer a clear path to enhanced efficiency, significantly reduced operational costs, and improved reliability for your critical boiler systems.

Stop letting your boiler silently waste money or dictate your production schedule with unexpected breakdowns. It’s time to take control.

Ready to stop guessing and start saving on your boiler operations?

Contact SteamBytes today for a no-obligation consultation. Let us show you how our IoT solutions can be tailored to empower your business to be more energy efficient. Visit our website or call us now to discover the future of precision boiler management!

Achieve 10% Savings on Annual Boiler Costs with Smart Technology

Unlock the power of IoT and AI-driven insights for safer, smarter, and more efficient boiler operations.